I believe the sketch supplied with the standard fillet gages can be misleading if you are gaging a fillet weld to what I would refer to as "AWS" requirements. The scribe line should not be used to "measure" a fillet weld. As already mentioned, it is not "calibrated" and is used only as a reference. The vertical distance from the horizontal plane to the tip of the gage is the only portion of the gage that is accurate and should be used to determine if the fillet leg dimension meets the minimum size requirement. The gage would have to be turned so that the base is against the vertical plane to measure the horizontal leg.

The scribe lines on the end used to measure concave fillet welds are for reference as well and should not be used to measure the leg lengths. The concave end of the gage is used to determine if the throat dimension meets the minimum throat dimension for an equivalent isosceles right triangle, it is not intended to be used to gage the leg dimensions.

There are several potential problems in using the scribe lines for gaging welds, one of the more serious problems is with parallax and the other problem being the accuracy of the scribe lines.

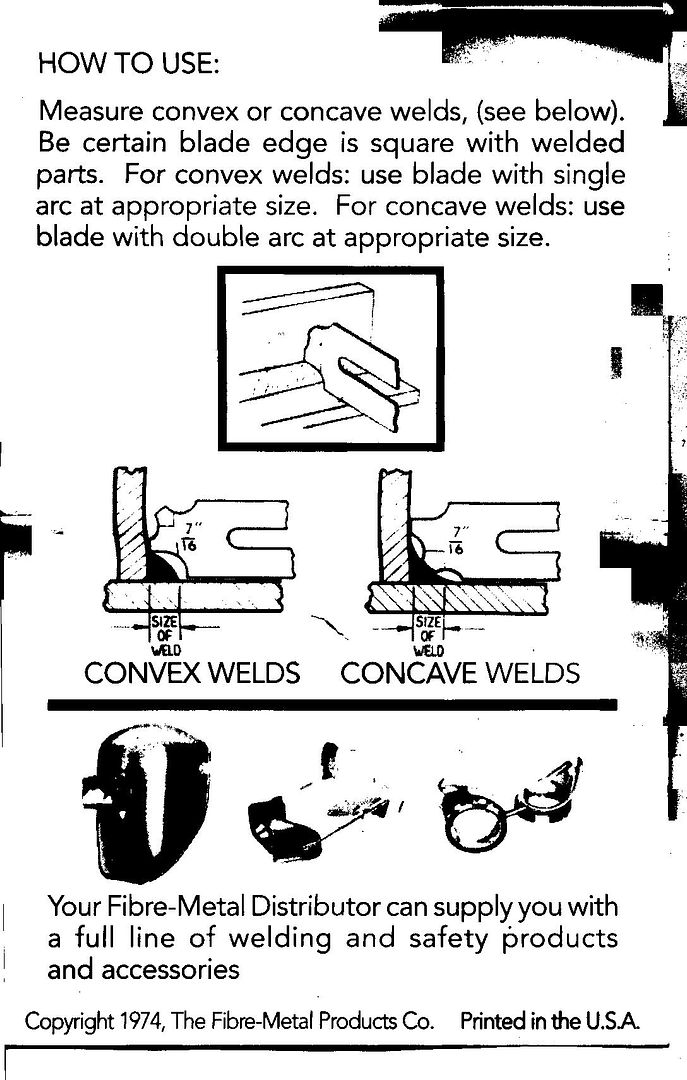

The attached sketches are use in my training class and may be useful in using the standard fillet gages more effectively.

As for oversized welds, there are only a couple of welding standard that I am familiar with that address "oversized" fillet welds and both of those only address "small" fillet welds not commonly used for structural applications, i.e., AWS D1.1, D1.5, or other structural welding codes. Oversized fillet welds are definitely not addressed by any of the ASME pressure vessel or piping code that I've worked with. That is not to say the subject of oversized fillet welds cannot be addressed by an in-house welding standard.

I had some trouble opening the attached file because it is "zipped". However, by saving it first and then opening it as a "MSWord" file, it seemed to work and opened up without a problem.

Best regards - Al