Rotor Blade Repairs

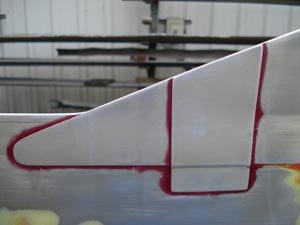

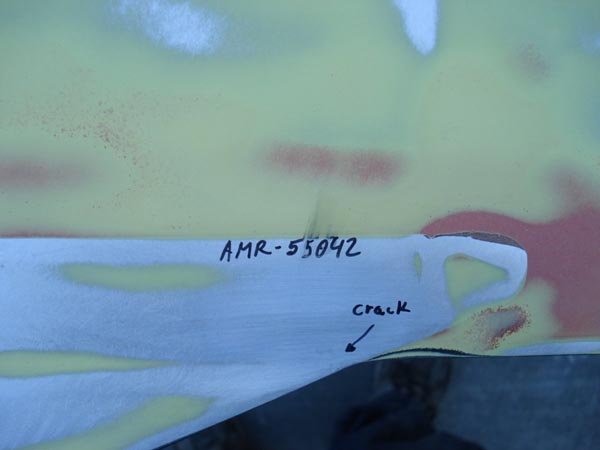

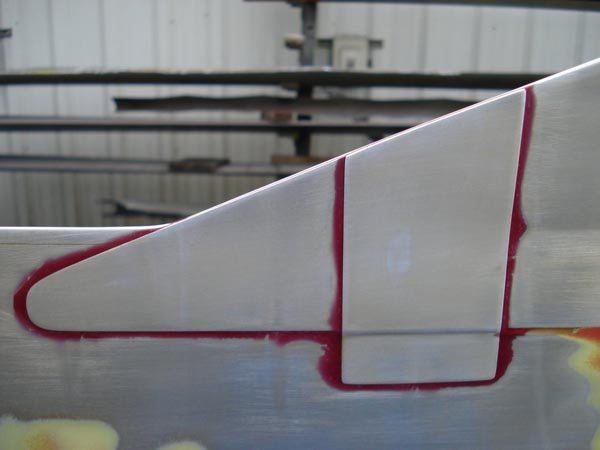

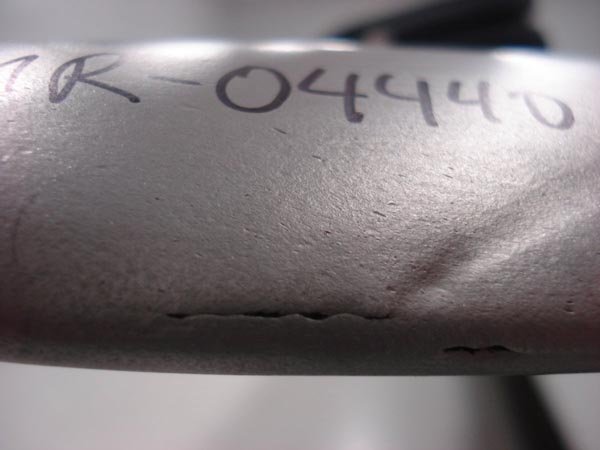

Inspections

We offer state of the art inspection procedures, most at no cost to you. We use several non-destructive techniques, including but not limited to:

Visual

Tap

X-Ray

Leak Detection

Dye Penetrant

Eddy Current

Ultra Sound

Twist Check

Droop Check

Thermal Imaging

Laser Sherography

Holographic Laser Interferometry

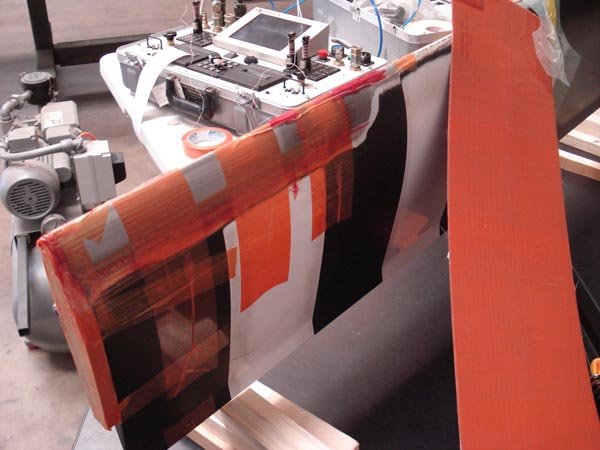

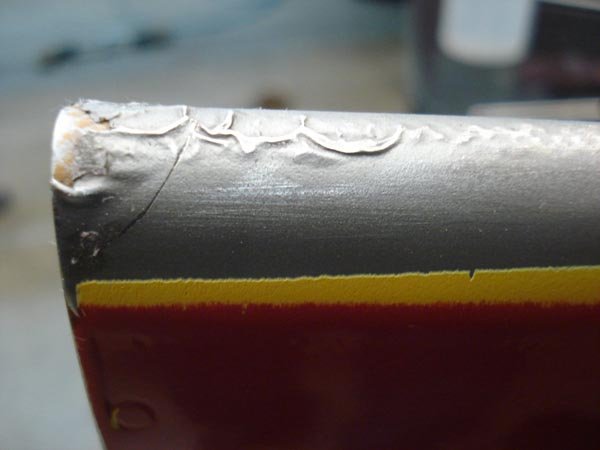

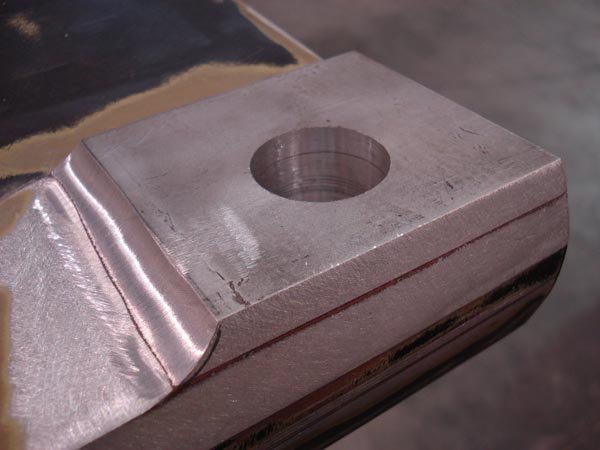

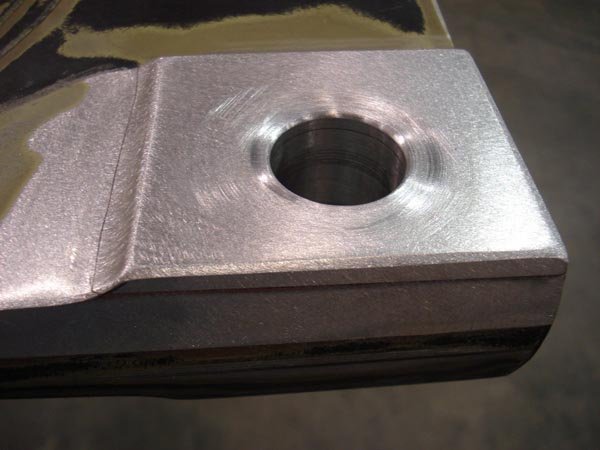

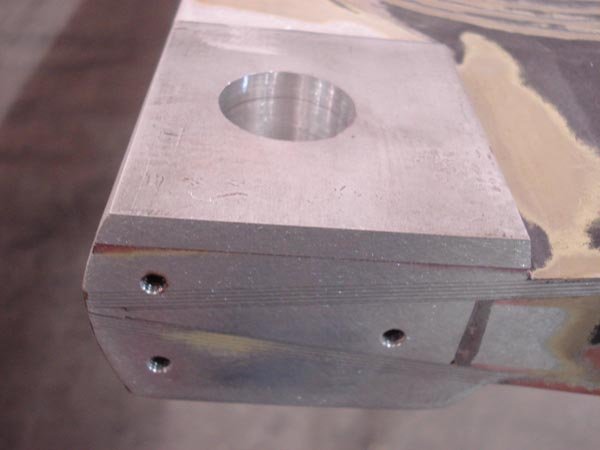

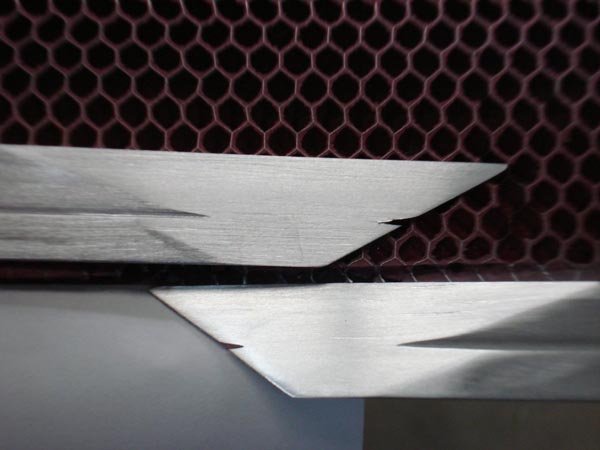

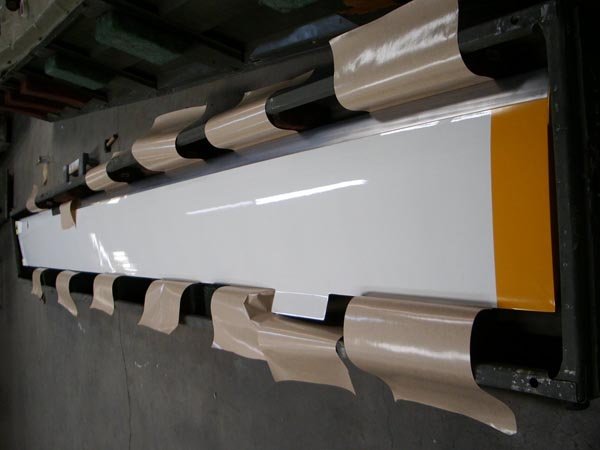

Overhaul

At HeliBlade we specialize in complete overhaul of your main and tail rotor blades. We take pride in our work and it shows in the finished product. Our body work and paint restores your blade to a like new condition and will hold up against our competition in all types of conditions. We do the job right the first time, so you can do yours. We offer competitive pricing and we will do our best to work within your schedule. Our typical turnaround time is two weeks from the reciept of a repair approval, but we can always do our best to get you in the air sooner.

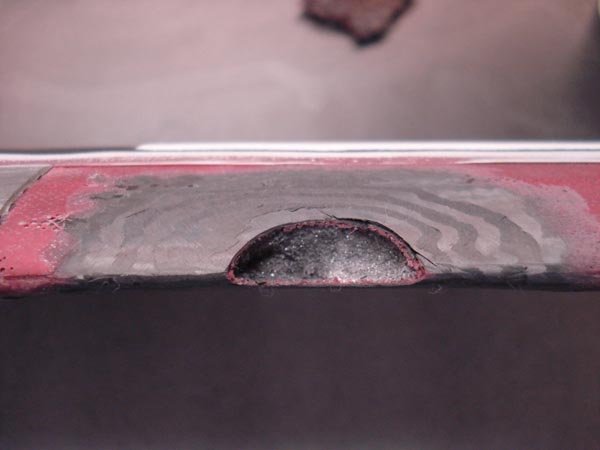

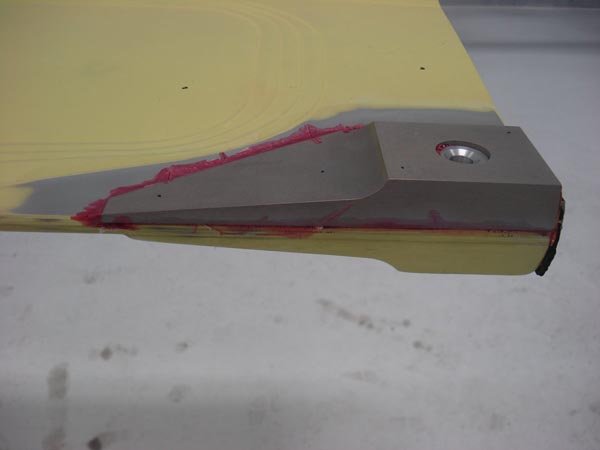

DER Approved Repairs

Our goal is to do everything possible to safely repair your rotor blades. We take pride in work and our innovative repairs. If, you have a blade with damage beyond the allowable limits or if another blade shop has scrapped it, bring it to us! We work closely with an FAA DER (Designated Engineer Representative) to repair every blade possible.

Before and After Photos

Click the titles below to view images and information