About 5 years ago I had a problem with my Rowland Consummate preamp. DC on the outputs.

I contacted Rowland about the problem. The preamp has a separate power supply enclosure, and the power supply measured within spec, so it was assumed the problem was in the potted gain modules, which were no longer available. The preamp went into storage.

About 3 years ago Jeff was able to find some old gain modules, which I gladly bought. Sadly, the problem that seemed to go away came back soon afterwards. The preamp went into storage again.

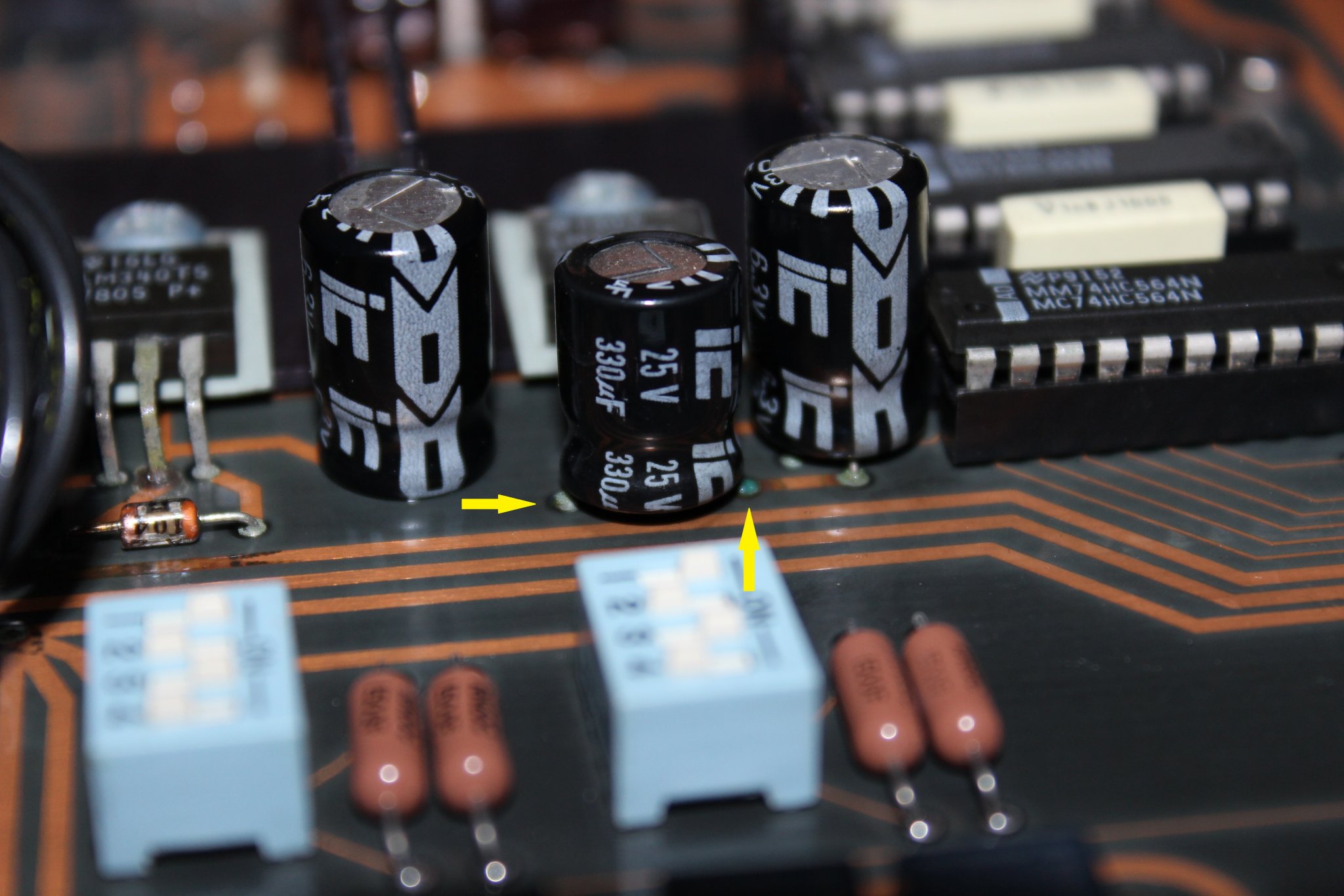

Since I started diy about 10 years, I am (very, very) slowly understanding how some simple circuits works. Also, reading the experiences of other diyers has been great to gain a better understanding of what does what, and why and how. Anyway, I had a feeling the electrolytic capacitors (1993 vintage) might be the cause of the problem. I opened up both enclosures to take detailed photos to find out the specifications of the original caps used. I needed this if I was going to find replacement capacitors (there is no service manual or schematic available to my knowledge).

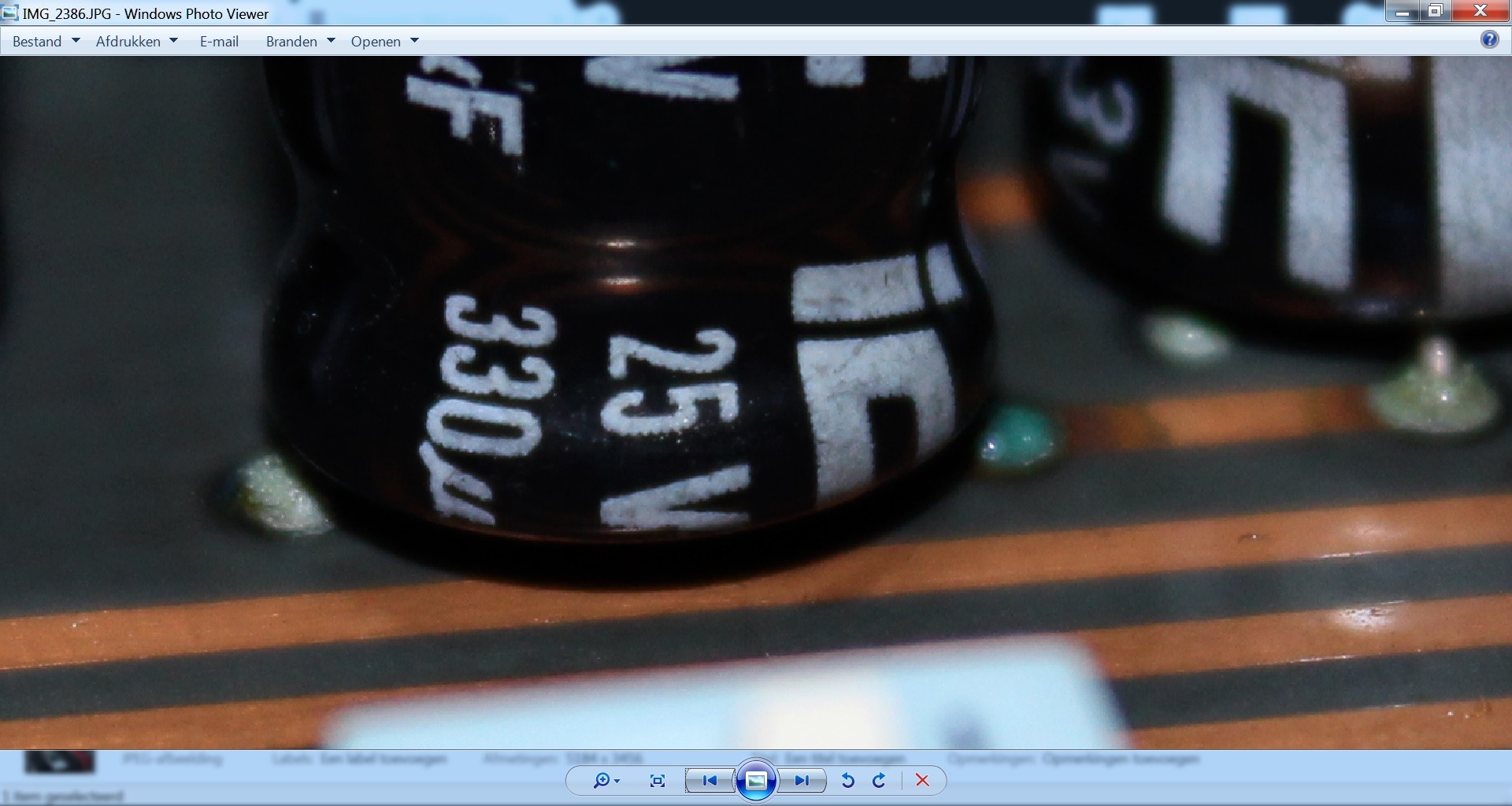

What I found when I zoomed in on one of the photo's in particular was what I assumed was a leaking capacitor.

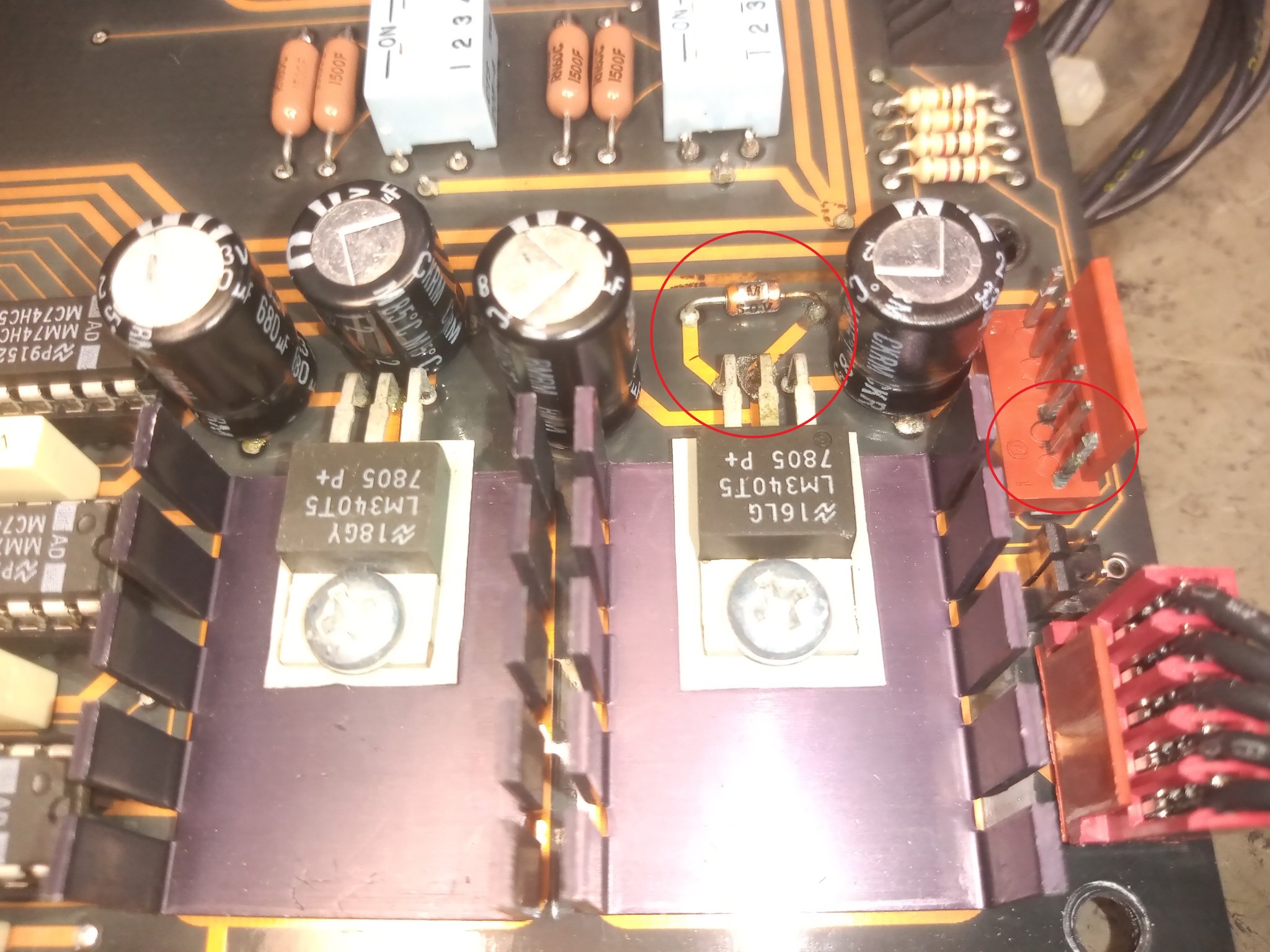

Long story short, yes there were a few leaking capacitors. They had been leaking electrolyte and it looked like they had damaged a few tracks on the pcb.

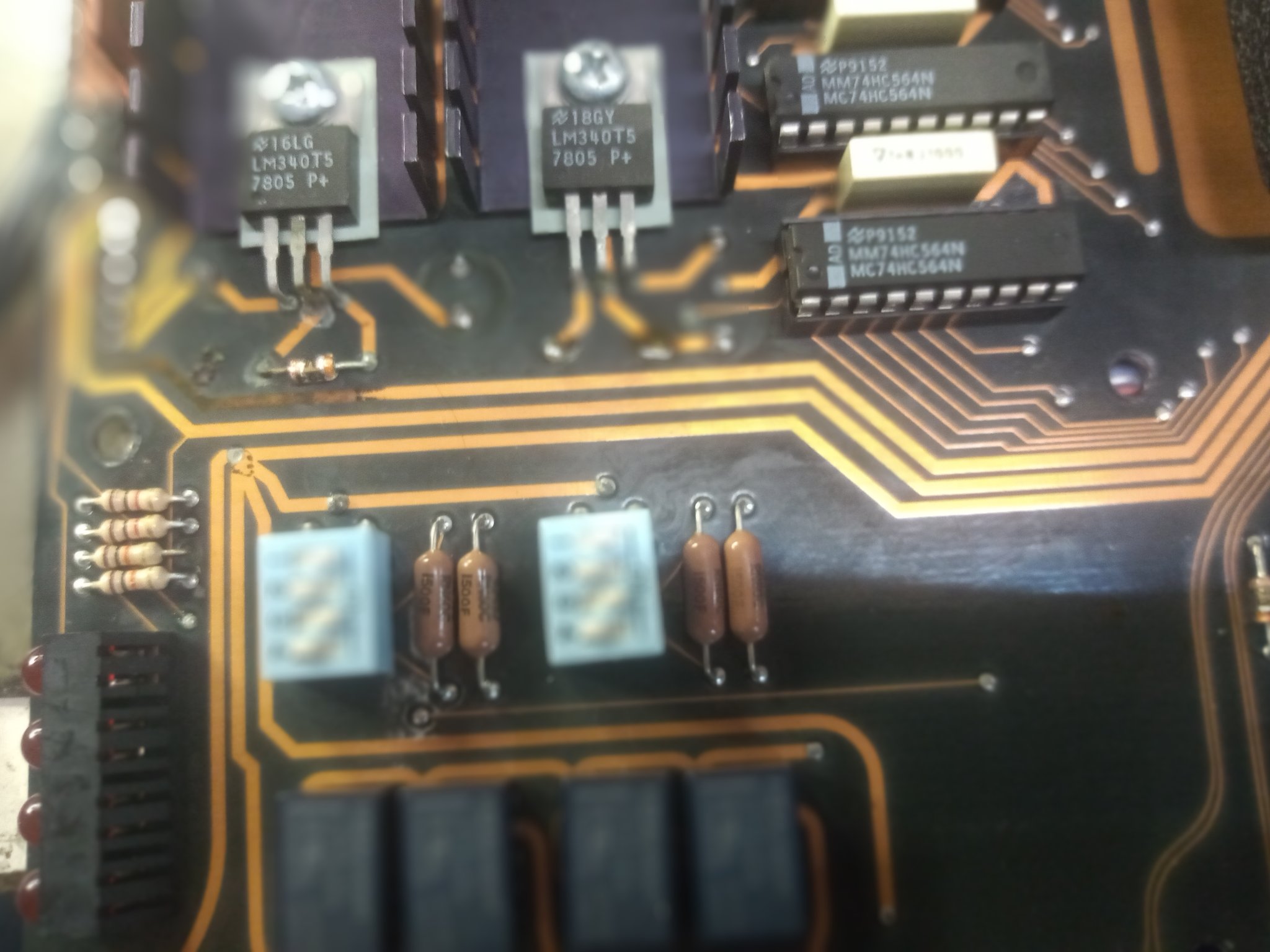

Knowing I was out of my depth and not wanting to damage such a rare and beautiful preamp, I found a technician with lots of experience. He removed all the electrolytic caps from both pcbs and was able to clean up the boards for me.

With the aid of photos sent to me by someone who had just recapped his own Consummate, my technician was able to reconstruct the damaged tracks of the amplifier pcb and replaced all the caps for me.

After 5 years, I am once again listening to a great preamp!

If you have vintage gear, please check for leaking electrolytic capacitors. Don't wait until the leaking electrolyte eats away the tracks and causes damage that cannot be repaired

I contacted Rowland about the problem. The preamp has a separate power supply enclosure, and the power supply measured within spec, so it was assumed the problem was in the potted gain modules, which were no longer available. The preamp went into storage.

About 3 years ago Jeff was able to find some old gain modules, which I gladly bought. Sadly, the problem that seemed to go away came back soon afterwards. The preamp went into storage again.

Since I started diy about 10 years, I am (very, very) slowly understanding how some simple circuits works. Also, reading the experiences of other diyers has been great to gain a better understanding of what does what, and why and how. Anyway, I had a feeling the electrolytic capacitors (1993 vintage) might be the cause of the problem. I opened up both enclosures to take detailed photos to find out the specifications of the original caps used. I needed this if I was going to find replacement capacitors (there is no service manual or schematic available to my knowledge).

What I found when I zoomed in on one of the photo's in particular was what I assumed was a leaking capacitor.

Long story short, yes there were a few leaking capacitors. They had been leaking electrolyte and it looked like they had damaged a few tracks on the pcb.

Knowing I was out of my depth and not wanting to damage such a rare and beautiful preamp, I found a technician with lots of experience. He removed all the electrolytic caps from both pcbs and was able to clean up the boards for me.

With the aid of photos sent to me by someone who had just recapped his own Consummate, my technician was able to reconstruct the damaged tracks of the amplifier pcb and replaced all the caps for me.

After 5 years, I am once again listening to a great preamp!

If you have vintage gear, please check for leaking electrolytic capacitors. Don't wait until the leaking electrolyte eats away the tracks and causes damage that cannot be repaired

I can't comment on the quality of the original caps. In my own builds, the only Illinois Capacitors I used were MKP caps that I bought from ApexJr years ago. I never tried (or looked up specs of) modern IC electrolytic caps.

For the recap, I looked up the specs of the caps that were in the amp and replaced the big snapins with slightly larger CDE SLPX (12 x 10000uF instead of 6800uF) and the smaller power supply and psu decoupling caps with low impedance United Chemicon KYB (usually a bit larger as well). I was amazed how low the ESR/impedance of those new caps was compared to the 30 year old ones, but I have no data from United Chemicon from 30 years ago so perhaps the new ones are just much lower because the technology has advanced.

Whatever the case, I am very happy to have my preamp working again. Seeing that I am using the Consummate with a factory Aleph 3 for the mid/high and a factory FirstWatt F5 for the bass of my Magnepan MG3As, it did not seem inappropriate to post this in the Pass Labs forum

My F4 monoblock clones are scheduled to replace the F5 for bass sometime in the future. And my diy Aleph 2s, after a through rebuild, may replace the factory Aleph 3, if I can get the sound anywhere near the magic of the Aleph 3. Thinking about it, that probably needs a recap as well!

For the recap, I looked up the specs of the caps that were in the amp and replaced the big snapins with slightly larger CDE SLPX (12 x 10000uF instead of 6800uF) and the smaller power supply and psu decoupling caps with low impedance United Chemicon KYB (usually a bit larger as well). I was amazed how low the ESR/impedance of those new caps was compared to the 30 year old ones, but I have no data from United Chemicon from 30 years ago so perhaps the new ones are just much lower because the technology has advanced.

Whatever the case, I am very happy to have my preamp working again. Seeing that I am using the Consummate with a factory Aleph 3 for the mid/high and a factory FirstWatt F5 for the bass of my Magnepan MG3As, it did not seem inappropriate to post this in the Pass Labs forum

My F4 monoblock clones are scheduled to replace the F5 for bass sometime in the future. And my diy Aleph 2s, after a through rebuild, may replace the factory Aleph 3, if I can get the sound anywhere near the magic of the Aleph 3. Thinking about it, that probably needs a recap as well!

Hi Albert,

There has been few threads over the years on recapping Aleph 3's. I know there's been others with photos but my quick search only came up with this scary one with an ultimately happy ending:

https://www.diyaudio.com/community/threads/my-aleph-is-unwell.383815/

Cheers,

Dennis

There has been few threads over the years on recapping Aleph 3's. I know there's been others with photos but my quick search only came up with this scary one with an ultimately happy ending:

https://www.diyaudio.com/community/threads/my-aleph-is-unwell.383815/

Cheers,

Dennis

Thanks Dennis. I had a brief look at the thread and that did not look good at all! I will read the whole thread tomorrow and takes notes.

I think I downloaded some photos from another thread (not the one you linked) some years ago for reference and also some info I think from another forum. I'll check on my server tomorrow to see what I have.

It is probably a good idea to open up my Aleph 3 to have a peek at the state, assuming I can see something just taking the cover off, i.e. without dismantling it.

It sounded so good again tonight now my preamp is back! But perhaps a good excuse to see what my lottery VFet does with the maggies mid/hi

The repaired Consummate replaced a diy Aleph P1.7 that works fine but is in a different league. I am sure it is not the design that is at fault but the execution. A friend built it for me 17 years ago using KK boards. I am not sure if the layout was great or not, but it is on my list to rebuild.

I already moved the psu to a separate box, with a long, shielded, umbilical. It helps, but it is nowhere near as quiet or relaxed as the Consummate, which also has the blackest background I have heard so far.

If there are no new good P1.7 pcbs around, I may try my hand at designing my own haha.

I think I downloaded some photos from another thread (not the one you linked) some years ago for reference and also some info I think from another forum. I'll check on my server tomorrow to see what I have.

It is probably a good idea to open up my Aleph 3 to have a peek at the state, assuming I can see something just taking the cover off, i.e. without dismantling it.

It sounded so good again tonight now my preamp is back! But perhaps a good excuse to see what my lottery VFet does with the maggies mid/hi

The repaired Consummate replaced a diy Aleph P1.7 that works fine but is in a different league. I am sure it is not the design that is at fault but the execution. A friend built it for me 17 years ago using KK boards. I am not sure if the layout was great or not, but it is on my list to rebuild.

I already moved the psu to a separate box, with a long, shielded, umbilical. It helps, but it is nowhere near as quiet or relaxed as the Consummate, which also has the blackest background I have heard so far.

If there are no new good P1.7 pcbs around, I may try my hand at designing my own haha.

I checked out the thread you mentioned, made notes and copied the photos to my server. Scary! Not sure what I am going to find in mine, but I will update when I have the courage to look.

I think a good look at and bench test of a lot of my gear is in order! I have too much gear and although much of the stuff doesn't have many hours on them, it would be worthwhile to give them all a once over.

I think a good look at and bench test of a lot of my gear is in order! I have too much gear and although much of the stuff doesn't have many hours on them, it would be worthwhile to give them all a once over.

Pass DIY Addict

Joined 2000

Paid Member

Thanks for sharing your experience and glad to hear that you got your equipment up and running again! What a great story!

I've been playing around with this long enough that I've learned when something starts misbehaving, I look at caps with the greatest amount of suspicion first. Electrolytic caps, even surface mounted ones, are problematic because they leak their electrolytic fluid. In my experience, anything over the age of 20 is suspect. The other problem that I've identified is solder joints on large-size connections (where a transformer is soldered to a circuit board) or where a row of header pins are soldered to a board are prone to cracking over time. This creates a minute gap that sometimes conducts electricity, other times not.

In either case, visual inspection with a bright light and a hand held magnifier are valuable diagnostic tools. I've revived a great deal of dead electronics simply by recapping a board. Sometimes, it's too late, the bad cap caused a cascade effect and other more challenging problems result. But, in 9 out of 10 cases, I've been able to resurrect a dead device with new caps and/or reflowing large solder joints that are made on the assembly line with "wave soldering" that does not sufficiently fill the gap with solder. See the attached images for things to look for.

I've been playing around with this long enough that I've learned when something starts misbehaving, I look at caps with the greatest amount of suspicion first. Electrolytic caps, even surface mounted ones, are problematic because they leak their electrolytic fluid. In my experience, anything over the age of 20 is suspect. The other problem that I've identified is solder joints on large-size connections (where a transformer is soldered to a circuit board) or where a row of header pins are soldered to a board are prone to cracking over time. This creates a minute gap that sometimes conducts electricity, other times not.

In either case, visual inspection with a bright light and a hand held magnifier are valuable diagnostic tools. I've revived a great deal of dead electronics simply by recapping a board. Sometimes, it's too late, the bad cap caused a cascade effect and other more challenging problems result. But, in 9 out of 10 cases, I've been able to resurrect a dead device with new caps and/or reflowing large solder joints that are made on the assembly line with "wave soldering" that does not sufficiently fill the gap with solder. See the attached images for things to look for.

Attachments

Thanks for the info and very clear photos.

I have an old (early 1980s) Sherwood S6040CP poweramp in storage (I never throw stuff away ).

).

It was my main amp in the 80s and 90s, until one channel kept dropping out. I had it looked at more than once (I had not yet started diy then) but the problem was never fixed (it kept coming back), so it went into storage. I remember it as a nice amp, but that was before I bought a second hand Aleph 3. Still worth opening up for an inspection. With a bit of luck it falls into the 9 out of 10 category, and a recap and reflow of the solder joints is all that's needed. If so, it may be a good match for bass on my bi-amped magnepan mg3as.

I have an old (early 1980s) Sherwood S6040CP poweramp in storage (I never throw stuff away

It was my main amp in the 80s and 90s, until one channel kept dropping out. I had it looked at more than once (I had not yet started diy then) but the problem was never fixed (it kept coming back), so it went into storage. I remember it as a nice amp, but that was before I bought a second hand Aleph 3. Still worth opening up for an inspection. With a bit of luck it falls into the 9 out of 10 category, and a recap and reflow of the solder joints is all that's needed. If so, it may be a good match for bass on my bi-amped magnepan mg3as.

Pass DIY Addict

Joined 2000

Paid Member

Good luck with reviving your Sherwood, Albert. Caps are pretty easy to replace, stick with the same (or very close - within 10%) of the original uF spec and same or higher (never lower) voltage rating. Work slowly and carefully, some mass produced boards are easy to damage by lifting a trace off of the PCB. One interesting thing is that caps can fail without showing outwardly obvious signs. Because the cap "looks" good and you can't see any electrolytic fluid (wet or dried) does NOT mean the cap is trouble free. If it's from the 1980's replace ALL caps.

For reflowing solder joints, check with a bright light and a magnifier. solder joints around caps, resistors, and other small items are likely to be fine. Solder joints for larger/heavier items are most suspect. These are places that typically require a large amount of solder and wave soldering likely didn't get enough solder to form a good mechanical joint.

For reflowing solder joints, check with a bright light and a magnifier. solder joints around caps, resistors, and other small items are likely to be fine. Solder joints for larger/heavier items are most suspect. These are places that typically require a large amount of solder and wave soldering likely didn't get enough solder to form a good mechanical joint.

- Home

- Amplifiers

- Pass Labs

- Leaking electrolytic capacitors nearly destroyed my old preamp - A cautionary tale