The Perfect Fan Shroud Position

If you’re running a belt-driven fan, there are a few things you need to do in order to maximize the engine cooling that the fan can provide. It’s critical that the fan be positioned properly within the fan shroud and that there is just enough clearance around the fan blades. The first thing we want to make sure is that you actually have a fan shroud. If you rely on a belt-driven fan for engine cooling, a fan shroud is a must to pull the air through the radiator. Without a shroud, air will take the path of least resistance, pulling air from over and under the radiator instead of through it.

Most people that have cooling problems with a belt-driven fan at idle and slow speeds don’t have a shroud – their fan is drawing very little airflow through the radiator, and most of their cooling comes from ram air being driven through the radiator at speeds above 40 mph.

If you have a fan shroud, the position of the fan blades in the shroud is very important to maximize airflow. Looking from the side of the engine, the fan blades should be half in and half out of the shroud. If the fan is too far inside of the shroud, it won’t pull as much air through the shroud as it could. Instead it will create turbulence inside the shroud, spinning the air, but not efficiently pulling it through. If the blades are not far enough inside the shroud, the fan will pull air from around the shroud rather than through it.

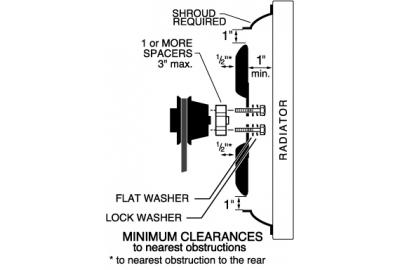

We manufacture a variety of fan spacers to move the fan forward and rearward, letting you achieve the optimal position. You can use 1 or more spacers – up to 3 inches in total. Make sure you use Flex-a-lite spacers; using any other brand with a Flex-a-lite belt-driven fan will void the warranty.

It’s also important that the fan blades do not extend past the top, bottom or sides of radiator surface. This causes dissimilar resistance along the length of the fan blades, which stresses them.

The other very important fan to fan shroud measurement is the distance around the circumference of the fan and the circular opening of the shroud. If there is too much space here, the fan won’t be as efficient as it could be in pulling air through the radiator. If there is not enough clearance, you run the risk of the fan contacting the shroud with natural engine movement and body flex that affects the radiator and fan shroud mounting. This can damage the fan shroud and the fan. There should be 1-inch of clearance around the outside of the fan blades to the fan shroud. The last measurement you should check is the distance from the face of the fan to the radiator. There should be at least 1 inch of clearance between the two. This is to accommodate normal engine and radiator movement, and also the flex that occurs in the fan blades at higher engine rpm.

Checking these measurements when running a belt-driven fan and a fan shroud will solve overheating problems and fan contact problems caused by improperly placed fans and shrouds.